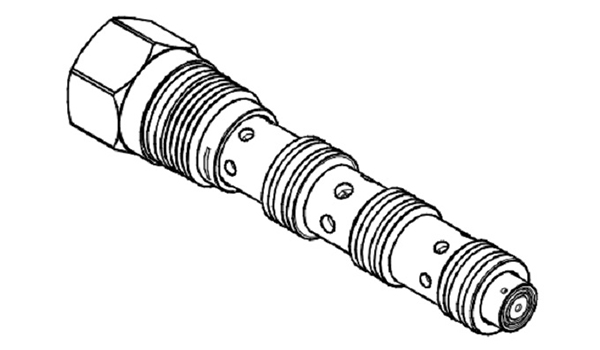

Flow Control Valves VFSC-02

- Home

- Products

- Cartridge Valves

- Flow Control

- Flow Control Valves

Features

- Synchronizing flow divider/combiners are sliding-spool, pressure-compensated devices used to split flow in one direction and combine flow in the opposite direction. With a synchronizing feature, these valves can be used to allow two hydraulic cylinders to fully stroke and synchronize at the end of the stroke. When the first cylinder has reached the end of its stroke, a pressure-compensated, reduced flow is metered to or from the second cylinder until it also reaches the end of its stroke.

- Operating characteristics cause the leg of the circuit with the greatest load to receive the higher percentage of flow in dividing mode. If a rigid mechanism is used to tie actuators together, the lead actuator may pull the lagging actuator and cause it to cavitate. Operating inaccuracy will cause the eventual lock-up of the system. If the mechanical structure is not designed to allow for the operating inaccuracy inherent in the valve, damage may occur.

- In combining mode, compensating characteristics will cause the leg of the circuit with the lowest load to receive the higher percentage of flow. If a synchronization feature is not included, an additive accuracy error will be experienced with each full stroke of the actuator.

- The synchronization feature provides bi-directional static error correction.

- Divisional and combining accuracy are equal.

- Specifications

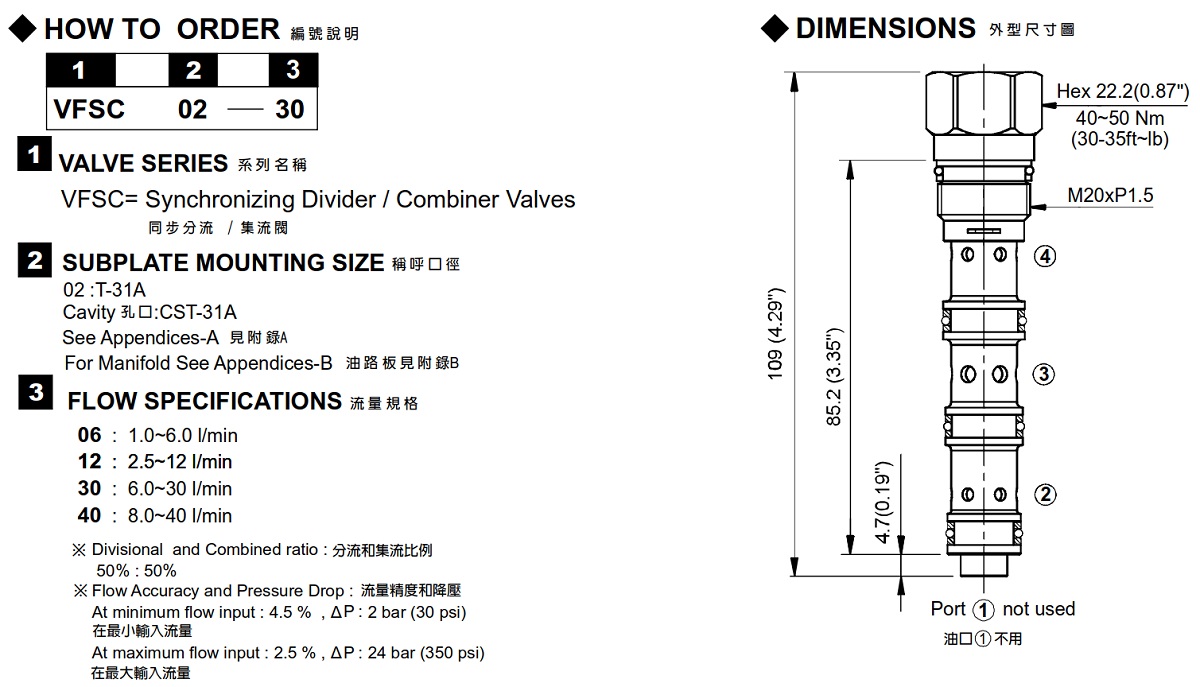

- How to Order

| Model Number | Maximum Pressure (bar) | Flow (lpm) | Weight (kg) |

|---|---|---|---|

| VFSC-02 | 350 (5076 psi) | *~40 ( *~10.57 gpm) | 0.2 (0.55 Ibs) |

| Fluid Type | ISO VG 32, 46, 68 | ||

| Viscosity (cSt) | 10~400 (59~1854 SSU) | ||

| Operating Temperature (°C) | -30~100 (-22~212°F) | ||

| Contamination Level | ISO4406. 20/18/15 NAS1638. 9 | ||